DRYIT Semi-Continuous Tray Drier

Practical Action

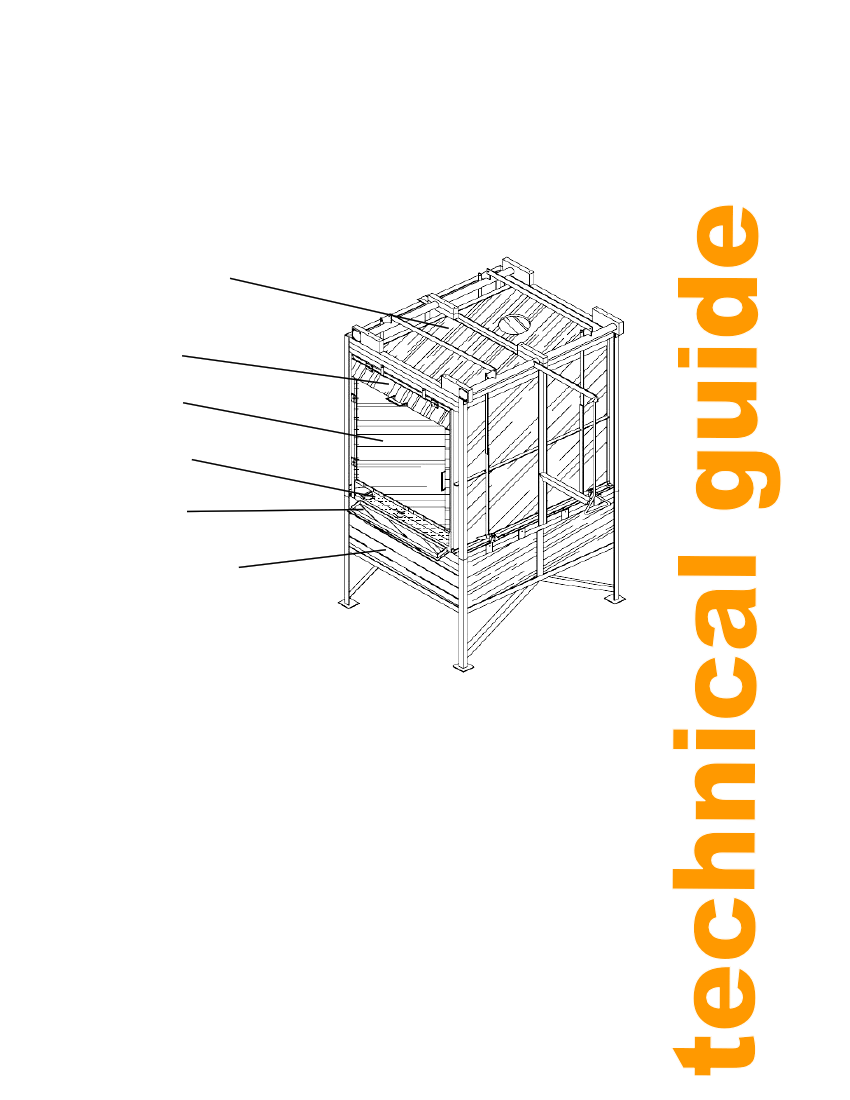

The trays, cladding and doors are shown in the position on the completed drier in figure 2.

Drying cabinet

cladding

Door

Door

Trays

Door

Base cladding

Figure 2: Cladding trays and doors

Construction Of Tray Drier

This section describes each major component together with a possible construction

procedure.

Base Frame

See drawing TD001

The base is made from mild steel angle, steel bar and steel plate. It consists of two

rectangles, 1110 x 1420 mm with four legs welded on the outside at the corners, bracing,

feet and two tray supports.

Mild steel angle is usually manufactured with a radius on the inside corner. Therefore, for the

legs to fit closely to the rectangles' outside corners, the corners must not be sharp. A way to

avoid sharp corners is to use 'snub' ends, as shown in figure 4.

7